Recently, EKKAMAI was invited to participate in the 2025 Indonesia Jakarta International Machinery Manufacturing Expo (Expo Period: December 3-6, 2025; Venue: Jakarta International Expo Center, Indonesia). The company made a brilliant appearance with its industrial dry ice cleaning and laser cleaning technologies and equipment, attracting a huge flow of visitors at the exhibition site and gaining significant attention and cooperation intentions from overseas customers.

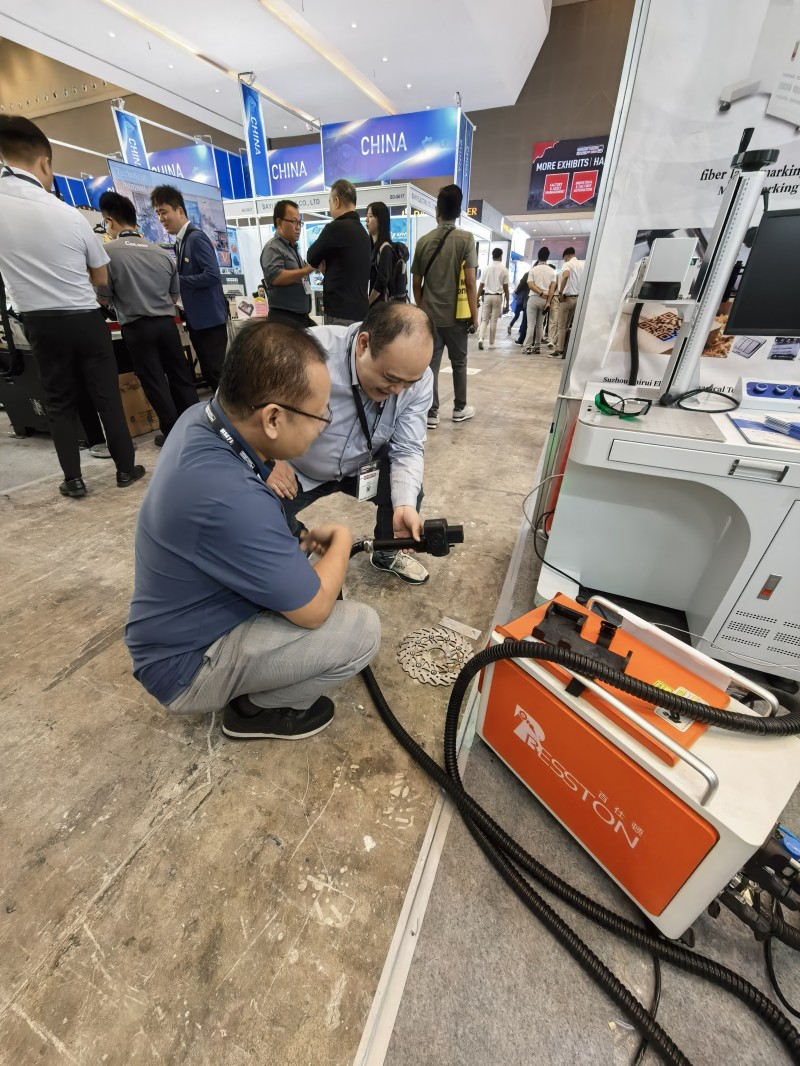

At the expo site, EKM Environmental Technology’s booth remained crowded with visitors throughout the event. From the eye-catching booth sign at the entrance of the exhibition hall to the laser marking machine operation and laser cleaning machine demonstration in the on-site display area, the company intuitively showcased the efficiency and convenience of its equipment. The staff also provided one-on-one guidance to local Indonesian customers on operating the laser cleaning machine, allowing them to personally experience the ease of use and cleaning effect of the technology. Many customers frequently took videos of the operation process with their mobile phones and constantly asked the staff about details such as equipment application scenarios and maintenance costs, showing strong interest in the advanced nature of Chinese cleaning technology.

During the expo, EKM Environmental Technology not only reached preliminary cooperation intentions with multiple groups of overseas customers but also achieved on-site orders. The person in charge of a local Jakarta-based auto parts manufacturer, after experiencing the cleaning effect of the dry ice cleaning machine on molds, signed a procurement agreement with EKM on the spot. He said, “Our factory used to clean molds with chemical reagents, which not only caused heavy pollution but also corroded the molds and affected their service life. EKM ‘s dry ice cleaning machine has completely solved these problems, and the cleaning efficiency has increased by more than 3 times compared with before.” After signing the agreement, the person in charge also took a group photo with EKM ‘s staff to record this cooperation moment. Similar scenarios occurred many times during the expo, fully demonstrating the appeal of Chinese environmental protection cleaning technology in the Southeast Asian market.

Southeast Asian Industrial Cleaning Market: An Upgrade Wave Driven by Both Policies and Demand

From the perspective of market prospects, the Southeast Asian industrial cleaning sector is ushering in dual opportunities driven by policy pressure and demand upgrading. Its demand characteristics are concentrated in three key dimensions:

1. Environmental Compliance Becomes a “Survival Red Line”, Traditional Technologies Are Accelerating Elimination

Countries in Southeast Asia have entered a period of tightened environmental policies. In the first half of 2025, the Indonesian government directly shut down 3 steel plants due to excessive emissions, clearly conveying a “zero-tolerance” attitude towards environmental supervision. As early as 2023, the Philippines passed a bill to completely ban the import and sale of industrial detergents containing non-biodegradable surfactants, and non-compliant enterprises will face full-chain accountability. This has put traditional cleaning methods that rely on chemical reagents and manual polishing in a “compliance crisis”. In Malaysia’s electronics manufacturing industry alone, more than 60% of enterprises are seeking alternative solutions due to the soaring cost of chemical cleaning waste liquid treatment. Environmental protection cleaning technology has transformed from a “bonus item” to an “access certificate”.

2. Manufacturing Upgrade Spawns Rigid Demand for “Precision Cleaning”

Southeast Asia is becoming a core destination for global manufacturing transfer, and the cleaning demand in segmented industries shows a trend of professional upgrading. In the auto parts sector, the market size of Malaysia is expected to reach 5.4 billion US dollars by 2033. The aging of vehicles and the rise of electric vehicles have driven the demand for efficient cleaning of molds and engine components. Traditional methods are difficult to adapt due to their tendency to damage workpieces and low efficiency. The electronics manufacturing sector is even more prominent. With the expansion of production capacity of IoT devices and precision chips, Malaysia’s precision cleaning market is growing at an annual rate of 5.5%. Enterprises’ demand for “zero-residue and non-damaging” laser cleaning technology has surged. In Penang Electronics Industrial Park alone, more than 100 enterprises have publicly tendered for environmental protection cleaning solutions. This demand shift from “extensive cleaning” to “precision maintenance” has created a blue ocean for technology-oriented enterprises.

3. Cost Control Forces the Choice of “High Efficiency and Low Consumption”

Southeast Asian enterprises always focus on “cost-effectiveness” when choosing cleaning technologies. The efficiency of manual cleaning is only 1/3 of that of laser cleaning, and labor costs increase by 8%-10% annually. Chemical cleaning requires additional waste liquid treatment costs (accounting for about 40% of the cleaning cost). In contrast, dry ice cleaning and laser cleaning do not require consumable replenishment or pollutant treatment, and the equipment operation cost can be reduced by more than 30%. Data from EKM ‘s on-site demonstration shows that the unit time efficiency of the laser cleaning machine in processing precision components is 2.8 times that of the local mainstream equipment. This dual advantage of “high efficiency + low consumption” accurately meets the practical demand of Southeast Asian manufacturing enterprises for “cost reduction and efficiency improvement”.

EKM Environmental Technology’s technologies perfectly match this demand. Dry ice cleaning uses food-grade dry ice as the medium, which does not produce secondary pollution during the cleaning process, effectively removes stubborn stains such as oil and rust, and does not damage the surface of workpieces. Laser cleaning, with its advantages of zero consumables, precise control, and adaptability to various materials, performs outstandingly in the field of precision component cleaning. These two technologies cover the multi-scenario cleaning needs from heavy industry to precision manufacturing, becoming the preferred solution for the upgrading and transformation of Southeast Asian manufacturing enterprises.

This participation in the expo has not only helped EKM Environmental Technology further open up the Southeast Asian market but also accumulated valuable feedback from overseas customers. In the future, the company will continue to optimize product performance according to local market demand, launch cleaning solutions more in line with the actual application scenarios of Southeast Asian enterprises, and help the local manufacturing industry achieve green and efficient development.